Chad Dotson, Waste Water Plant Manager

Chad Dotson, Waste Water Plant Manager

Chad Dotson, Waste Water Plant Manager

110 Lawson Street

Centerville, TN 37033

(931) 729-4265

The Town of Centerville wastewater treatment plant was established in 1968. It was a 350,000-gallon-per-day contact stabilization-activated sludge treatment plant. In 1984, it was upgraded to a 750,000 gal/day extended aeration-activated sludge plant. The most recent upgrade was completed in 2014, making the plant a 900,000-gallon-per-day plant with a 2,000,000-gallon equalization basin.

Covering over 3 acres, the Centerville Waste Water Treatment Plant is qualified to handle the town's waste needs for years. This plant plays a vital role in industrial recruitment by ensuring prospects of our ability to serve their needs.

Waste Water Testing

Waste Water Testing

The wastewater is delivered to the Duck River and undergoes extensive testing in the plant's spotless laboratory. Daily tests ensure the water meets all requirements set by state and federal regulations. The wastewater is cleaner than the water initially drawn from Swan Creek, unlike in years past when sewage was scarcely treated.

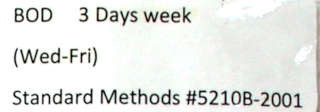

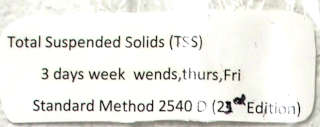

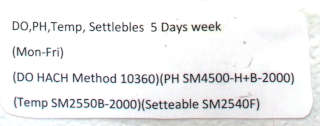

The plant performs several complex tests regularly to treat the wastes thoroughly. The testing requires constant reporting to the State, EPA, and other authorities to stay compliant. To illustrate the kinds of testing, the photos below are of labels posted above hanging clipboards of reports the staff complete daily or several times per week.

Biochemical Oxygen Demand

Total Suspended Solids

Dissolved Oxygen, Temperatures, and Settled Material

Dissolved Oxygen, Temperatures, and Settled Material

Parts of the Waste Water Treatment Plant

Water Quality Testing Laboratory

The laboratory plays a crucial role in keeping odors down and ensuring the efficiency of the treatment process. Like any modern chemistry lab, there is an array of specialized equipment for chemical and biological tests.

Precise stirring and mixing equipment adding chemical reagents

Precise stirring and mixing equipment adding chemical reagents A digital microscope tests for microorganisms

A digital microscope tests for microorganisms

Multi-staged separation of organic wastes

The EQ Basin is the largest tank in the plant. It measures 57 feet across and 19 feet deep and can hold up to 1.9 million gallons.

The EQ Basin is the largest tank in the plant. It measures 57 feet across and 19 feet deep and can hold up to 1.9 million gallons.

Aeration Blowers

Greg Edwards monitors the aeration of wastesThree 100-horsepower air blowers are used for aeration, introducing oxygen into the wastewater. This allows aerobic bacteria to break down the waste without creating excessive odors. The Aeration Basin is where oxygen is introduced. Microbiological activity here continues the treatment process.

Greg Edwards monitors the aeration of wastesThree 100-horsepower air blowers are used for aeration, introducing oxygen into the wastewater. This allows aerobic bacteria to break down the waste without creating excessive odors. The Aeration Basin is where oxygen is introduced. Microbiological activity here continues the treatment process.Clarifier Basin

Belt Press

This is the belt press. Its function is to "dewater" the sludge. The dried sludge is trucked offsite and used for fertilizer.

This is the belt press. Its function is to "dewater" the sludge. The dried sludge is trucked offsite and used for fertilizer.

Sludge Disposal